Open Vision™ Grind

A feature-rich grinding package that can be adapted to most grinding machines, powered by FANUC CNC controls.

HMI Software Designed for CNC Grinders

Open Vision™ Grind was developed to provide the best of both worlds - the features and performance grinding manufacturers demand, with the reliability and acceptability of FANUC CNC control systems. Open Vision™ Grind uses the same interface, regardless of the grinding machine configuration, so operators can easily move between grinders.

The software simplifies the grinding process for CNC grinding machines like:

- Universal Grinders

- ID / OD Grinders

- Vertical Grinders

- Surface Grinders

- Race Grinders

- Bore Grinders

- Roll Grinders

- Step Grinders

- Thread Grinders

- Creep Feed Grinders

Open Vision™ Grind Programmer

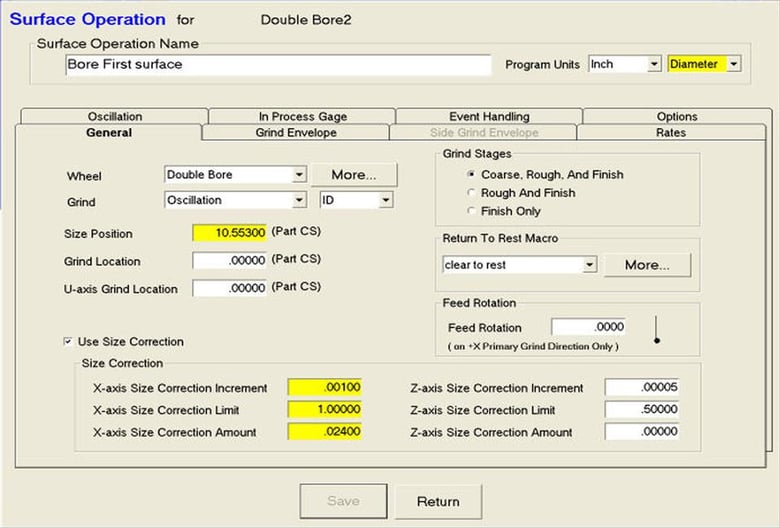

The built-in conversational programmer provides a quick and easy solution for developing complex grinding programs. Editing tools allow users to create new programs from scratch or copy existing programs and edit inputs to easily build a large database of part specific programs and greatly reduce changeover times. Open Vision™ Grind Programmer can be accessed via the HMI PC and/or a desktop PC.

The conversational programmer can be configured for:

- ID and OD Programming in one setup

- Plunge, Oscillation, Vector, and Contour Grind

- Mulitple Axes

- Multiple Wheelheads, Turrets, and Wheel Changers

- Complex Dress and Grind Contours

- AE or Wheel Load Gap Elimination

- Dual Path Grinding

- Multiple Dress Configurations and Tools

- InProcess Gage – Discrete or Analog Interface

Features for Vertical Grinders

- Programmable Library of Wheel Types and Quills

- Programmable Wheel Direction

- Wheel Changer

- Multiple Wheelheads on B-axis

- Calculated X & Z Grind Positions Based on B-axis Angle

- Dress Based on Wheel Load

- Dress From the Rear

- E-axis Editor

- Peel Grind

- Dual Path Programming

Features for Surface Grinders

- Oscillation, Plunge, Vector, and Surface Grind Types

- Separate Cross Feed Data for Coarse, Rough, Finish

- C-axis Indexing for Slot Grinding

- Dynamic Dress for Creep Feeding

- CNC Sine Bar

- Y / X Contour Grind

Features for Race Grinders

- E-axis Sweep and Plunge Roll Dressing

- Spherical Editor for Two Axes Dresser

- Crown Dress Editor

- Gap Elimination

- InProcess Gage – Discrete or Analog Interface

- E-axis Race Editor for Snap Angles, Race Angles, Double Straight, Gothic Arch

Features for Bore Grinders

- High Speed Oscillation

- Gap Elimination

- InProcess Gage – Discrete or Analog Interface

- Post Process Gage Interface

- Constant Power Infeed

- Skip Dress

- CBN Adaptive Dress

- CBN Wheel Conditioning

Features for Roll Grinders

- OVGrind’s Generic Sequence Editor for dubs & cutoffs

- In-Cycle override of wheel speed

- In-Cycle override of work speed

- Manual Handle Interrupt allowing the operator to override feed increment

- Continuous Traverse to semi-automatically discontinue feed increment

- Custom Roll Crown Editor for profiling Cosine Angle, Crown Width, Crown Height, Taper Adjustment, Plunge Groove, Spiral Groove

Features for Step Grinders

- Probing

- Constant Wheel Surface Speed

- In-Process Gage

- Post Grind Measuring

- Data Entry Locks

- Remount Wheel (Uses Last Wheel Offset)

- Gap Elimination: Acoustic Emission or Wheel Load

- Inch / Metric Data Entry (on-diameter OR on-radius)

Ready to Enhance Your CNC Grinder?

Let's talk about what Open Vision™ Grind can do for your CNC Grinding Machine.